|

modern machinery park Production in Aadorf high quality processing |

Vertikale Konturschneidmaschine

Almost all soft materials can be cut on the world's fastest CNC contour cutting machine. This cutting-edge cutting center is characterized by very high cutting speeds. In addition, any shapes with the most delicate contours and a high quality and precision can be cut.

Vertical contour cutting machine

Our CNC contour cutting machine, which is the fastest in the world, can cut almost all soft materials. This spearheading cutting center is characterized by its extremely high cutting speeds. In addition, it can cut any shapes with the most delicate contours, highest quality, and extreme precision.

CNC milling system

Our CNC milling system is suitable for materials of almost any hardness. It has a traversing range of 2000 x 4000 x 160 mm, which also allows machining of large workpieces. The CNC machining system is further characterized by fast acceleration and high consistency.

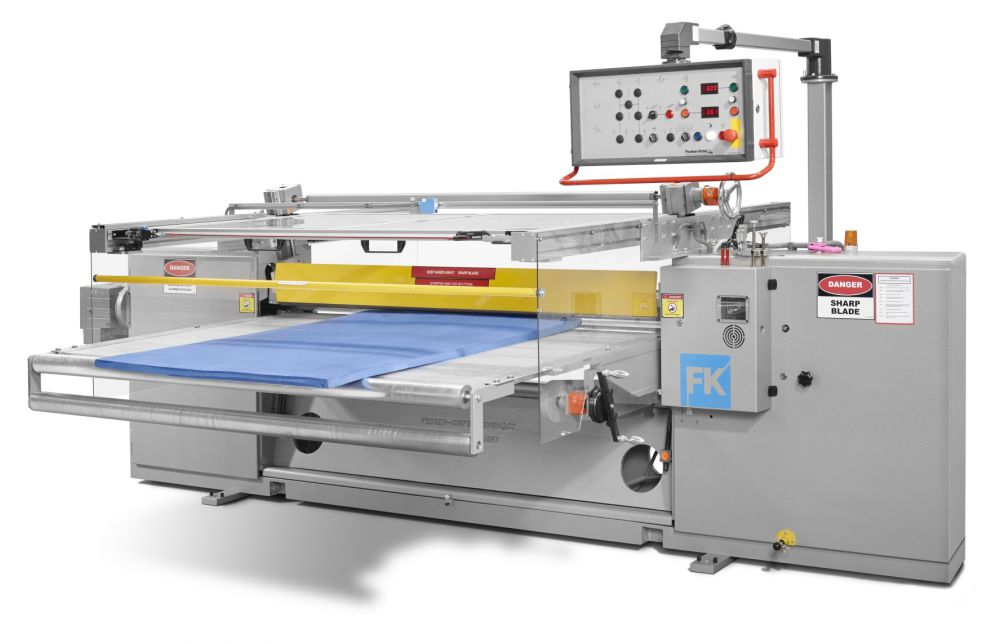

CNC cutting plotter

This automatic cutter can cut soft materials with thicknesses of up to 120 mm and a base of 3000 x 1550 mm. Its oscillating knife enables very precise cutting edges and dimensional accuracy.

Punching machines

Our punching workshop allows us to punch soft materials such as rubber, foams, and plastics with lengths of up to 1950 mm and widths up to 750 mm using inexpensive strip steel tools.

Thermal cutting / welding machines

In thermal welding, heated steel is used to bring the PE polyethylene foams into the desired shape and the foam is joined together permanently through mirror welding.

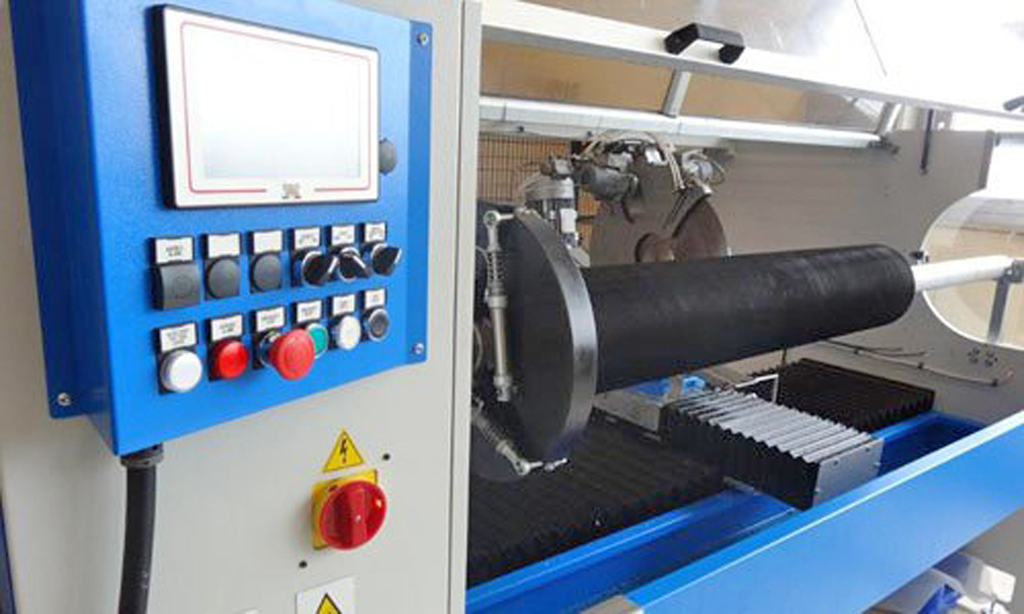

Reel slitter machine

The reel slitter machine can be used to cut sealing tapes and double-sided adhesive tapes of any length and width. It is optimized for the cost-efficient production of products such as cellular rubber sealing tapes, PU/PUR tapes, silicone sealing tapes, double-sided adhesive tapes, rubber bands, etc.

Plastic bending machine

The plastics bending and folding machine is designed to make thermoplastics such as acrylic glass, PE, PET, PP, PVC, and polystyrene malleable under heat, after which they can be bent into any shape.

Our extremely versatile and state-of-the-art machinery enables high-quality processing with the necessary efficiency.

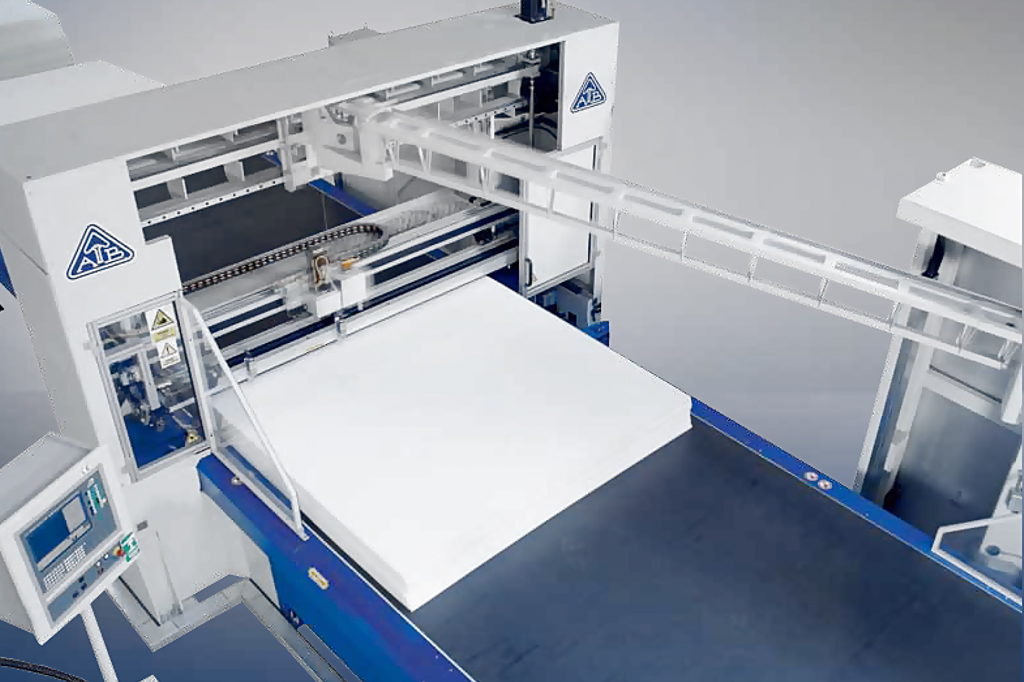

Horizontal contour cutting machine

Our CNC contour cutting machine, which is the fastest in the world, can cut almost all soft materials. This spearheading cutting center is characterized by its extremely high cutting speeds. In addition, it can cut any shapes with the most delicate contours, highest quality, and extreme precision.

CNC 5-axis water jet machines

The CNC water jet process makes it possible to explore the entire range of design options. This process is very precise and efficient. It can be used to produce parts with a thickness of up to 250 mm and a base area of up to 4000 x 2000 mm, depending on the material.

Automated cutting plotter

Our new cutting plotter is characterized by its high cutting speed and acceleration, intelligent tool control, and automated material handling. Combined with the modular design, the new cutting system is not only flexible, but also more efficient, faster, and more precise. The machine is designed for continuous use to process materials of any size. In particular, materials that are in roll can be processed very cost effectively.

Foam shape cutting machine

Our new foam cutting machine enables us to produce virtually all 3D molded components made of elastic foams based on predefined specifications. It allows for cost-friendly production of both positive (e.g., upholstered parts) and negative parts (e.g., packaging industry) whether in small or large series. The machine's solid design allows a compression ratio of 1:20, thus offering a high potential in the individual design of molded parts. Its robust knife bar with automatic knife adjustment guarantees a constant knife position and hence consistent product quality. Thanks to the state-of-the-art PLC control with an OP panel, production data can be saved for future retrieval thus guaranteeing optimal reproducibility of the molded parts.

Laminating machine/glue roll coating machine

These processes are used to permanently join together foam boards and foam parts made of PE or PUR foam.

Laser engraving / cutting machines

This process combines high productivity in laser cutting and laser engraving with high efficiency and precision. The large working area of 1,600 mm x 1,200 mm makes almost every industrial application possible.

3D printer

Our new 3D printer enables us to produce real objects in different colors based on three-dimensional data. The components are made of ABS (acrylonitrile-butadiene-styrene) thermoplastic. The ABS parts are durable and ideal for display models, functional tests, prototypes, product design, and even for the manufacturing of fasteners and mounting aids. The 3D printer measures 200 x 200 x 150 mm.

Foam flocking system

Our electrostatic flocking system applies a technique in which fibers of various colors and lengths are shot in glue using anelectric field. This technique enables us to make a surface silky smooth, giving it a refined appearance and feel. In addition, it gives the surface a three-dimensionality through clearly discernible relief. It can be used to fully or partially flock a wide variety of materials such as metals, foams, plastics, wood or rubber, textiles, and metal.

By using this website, you consent to the use of cookies and our privacy policy. Privacy policy

agree.

If you have any questions, please contact info@vibraplast.ch