Heat-Cold Insulation

Excellent insulation performance of solar collectors.

Online consulting!

?

A solar collector (also solar collector or thermal collector) is the core of a thermal solar system, with which heat can be obtained from the radiation energy of the sun (solar energy).?

?

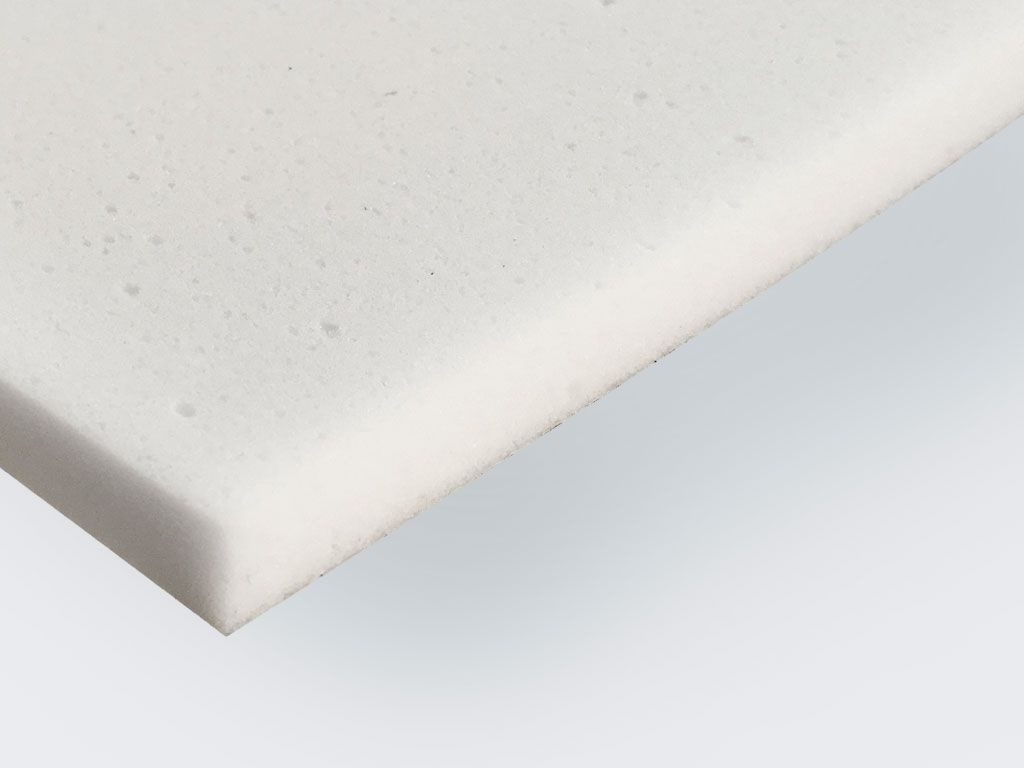

The lightweight and flame-resistant melamine resin foam Basotect G+ is used on the side walls and rear of solar flat-plate collectors. The Basotec melamine foam has an excellent insulating performance even at high temperatures over a long period of time and has a positive influence on the air exchange in the collector even under the most diverse climatic conditions. Unlike other insulating materials, the melamine foam can be cut into various shapes. The Vibraplast can carry out all foam processing forms swiss made in house, e.g. the shape of the pipes can be milled into the foam with the solar fluid.? The Basotect material is flexible, fibre-free and can be easily cut to the required contours.

The collectors should absorb as much sunlight as possible over their entire service life, thereby predestining the more long-lasting and temperature-resistant Basotect G+ for this purpose. The melamine foam also releases practically no volatile substances that hinder solar radiation, e.g. through fogging on the collector glass or collector pane, thereby reducing the efficiency of the solar system. Due to the very good thermal conductivity of < 0.035 W and an intelligent design of the insulating material parts, the melamine resin foam achieves the same insulating performance as, for example, mineral wool with less material input. Thanks to Bastotect melamine foam, the efficiency of flat-plate collectors is further increased and users receive an economically even more interesting system.?

Frequently asked questions (FAQ)

The melamine foam standard panels are supplied as untrimmed raw panels.

The ordered usable dimensions are guaranteed, but protruding material (foam, fleece, SK-foil etc.) is possible.

Small air inclusions or blowholes on the foam top of Bastotec laminate foams can occur and are created during production. Unfortunately these cannot be prevented. However, the air inclusions have no influence on the absorption capacity.

Our melamine foams Basotect? meet both of these requirements in equal measure, highly sound-absorbing and with very good thermal insulation properties.

Basotec? melamine foam has the BKZ 5.2 (hardly inflammable with medium smoke formation)

According to your specifications, we can produce almost all geometries on our wide range of processing options such as punching, water jet cutting, contour cutting, shape cutting or cutting plotter. Which process is best suited for the desired foam cutting depends on the foam used as well as the required quality and quantity.

The thermal conductivity is decisive for the thermal insulation properties of an insulation material. The thermal insulation property indicates which thermal energy (W) flows through a component per meter (m) at a temperature difference of 1 Kelvin. The unit of measurement is W/mK and is abbreviated as small lambda (?). The basic rule is that the smaller this value, the better the thermal insulation property of the insulating material. Examples: PUR foam 0.037 / polyester fibre mats Vibra?fibre 0.037 / melamine foam Basotect? 0.033