Archive Packaging

Museum Art Gallery

Archive Packaging

Invaluable works of art deserve optimal protection in archiving.

Online consulting!

Archive packaging for art objects and artifacts.

Historical artifacts deserve optimal foam archiving so that everything is preserved for future generations.?

Only acid-free and plasticizer-free plastic products should be used for the packaging of art objects. In general, no chloride compounds (e.g. PVC) should be used. Suitable products are polyethylene terephthalate e.g. Mylar, polyethylene e.g. Dibond, polycarbonate e.g. Lexan, Tuffak or Makrolon, polymethyl methacrylate e.g. Lucite, Plexiglas or Perspex and polypropylene. Polyester, polystyrene and silicones are less useful, the latter release acetic acid especially during drying.

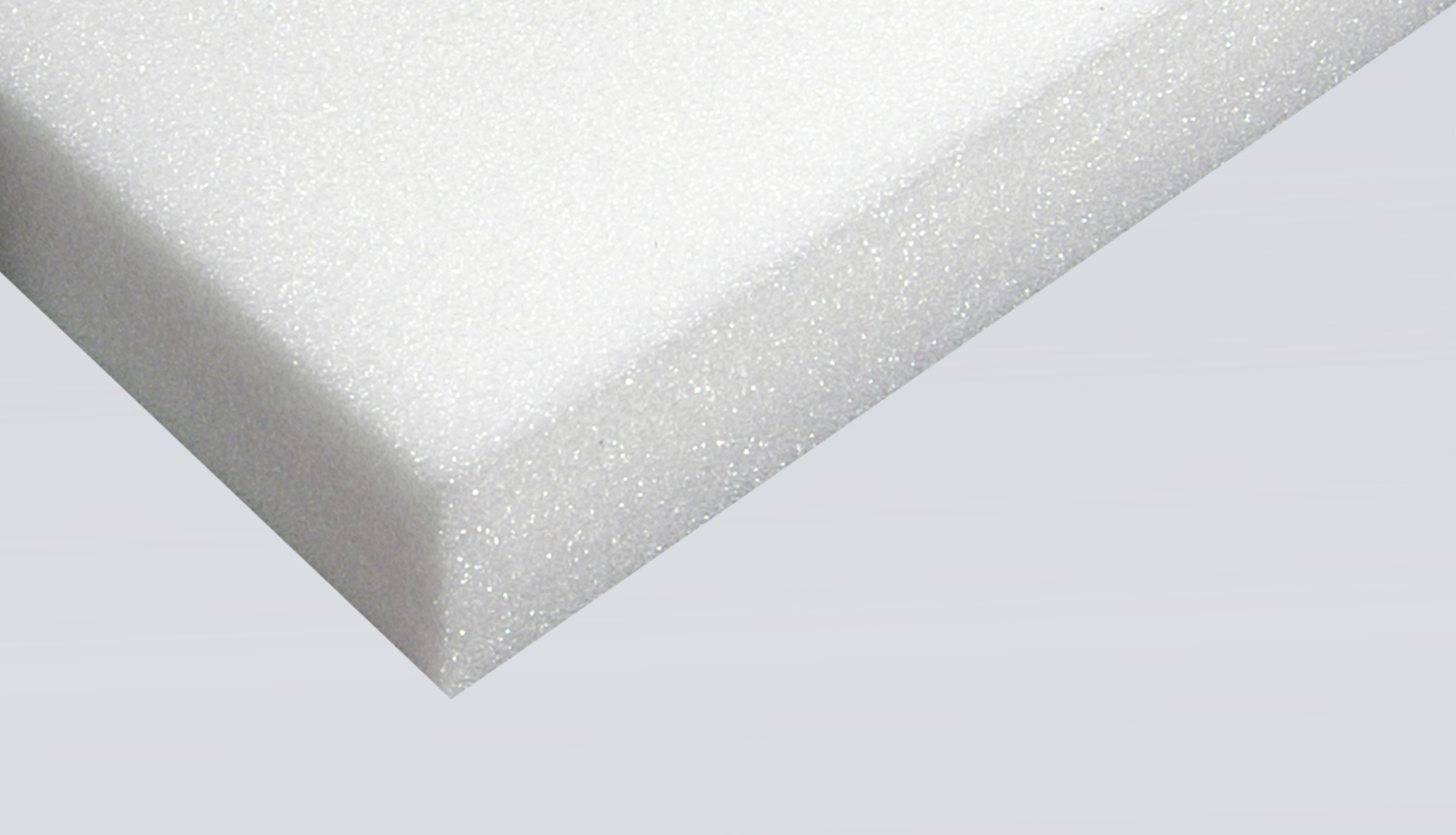

Among the foams, physically expanded low-pressure polyethylene foams (e.g. Ethafoam, Plastazote) are harmless as long as they are not coated with adhesive tape. It should be noted that they are not hygroscopic (not water-attracting).

PLASTAZOTE packaging foams

The expert choice of packaging for plastic packaging includes high performance cross-linked polyethylene foams (Plastazote) with closed cells.

?

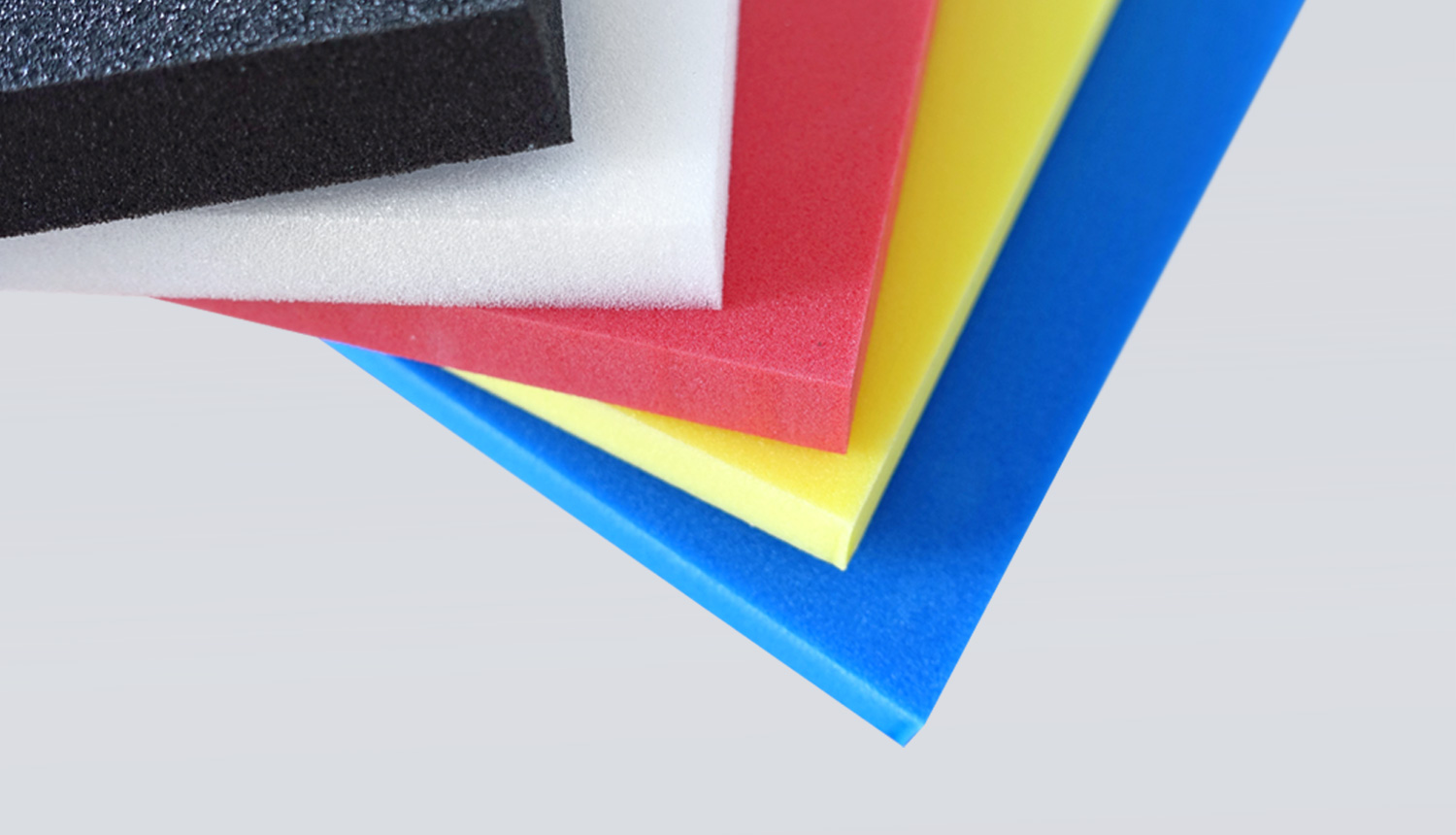

Whether works of art of inestimable value, historical artefacts or preserved specimens of animals or plants in museums of natural history, all objects must be optimally protected during exhibition, transport or storage in archives. In many museum and gallery applications the use of high purity polyethylene foam is the desired standard, with Plastazote being the reference for purity and uniformity today. PLASTAZOTE FOAM is a high purity cross-linked polyethylene foam with closed cells. It is manufactured using a unique high pressure fabric impregnation process which guarantees exceptional purity and uniformity. These foams are the ideal materials for security packaging and have a proven track record in museums and galleries. Plastazote foams are completely free of fluorocarbons and chlorofluorocarbons (HFCs, CFCs, HCFCs) and volatile organic compounds (VOCs) and contain no potentially corrosive or discolouring residues of foaming additives. Plastazote's highly durable, stable and odourless foams are available in a range of different densities and attractive colours. The coloured foams use solid pigments which are fully integrated into the polymer matrix and as a result do not migrate or leach.

Plastazote foams are easy to machine. It is manufactured in blocks of 2m x 1m and can be cut, sawn, milled, punched, split, thermoformed, water jet cut, laminated and welded to produce virtually any shape required. Due to the closed cell structure, the materials can be easily freed from dirt. For this purpose, standard cleaning agents - household soap - in combination with warm water are sufficient. High purity, non-dyeing, acid and ammonia free, water and chemical resistant, good gripping elasticity, good energy absorption, extraordinarily attractive appearance are only some of many outstanding properties.

TYPICAL APPLICATIONS:

General packaging and padding, foam lining of showcases, foam lining of boxes and drawers, special inserts inserts boxes and cases, book stands, worktop supports for sorting samples, storage and packaging of fragile objects, foam padding of pictures ecc.?

?

vibra? Museums Art Foam

?

Vibraplast AG offers you professional foam products for optimal packaging, storage, securing or shipping of art objects and collection items in museums, libraries, archives and galleries.

Be it for the permanent safekeeping, securing and preservation of archival materials or the safe transport of art objects, our foams are ideally suited for this task.

Frequently asked questions (FAQ)

The compression hardness or also called compression resistance is the pressure required to compress a foam. At a compression hardness of 60, 6.6 kPa (kiloPascal) is required to compress the foam to 40%. The compression hardness of a foam is its strength.

The density is the weight of the foam in kg/m? (kilogram per cubic meter). The weight or density of the foam is also an indicator of quality, the higher the density, the more long-lasting the quality. However, the density has nothing to do with the perceived degree of hardness. As a rule, lighter foams are cheaper because less material is needed.

The density and compression hardness describe the technical quality of a foam. The compression hardness describes the indentation behaviour of foams at a defined force. The higher this value, the harder the foam feels. An important quality feature of a foam is its density or volume weight (m3 kilograms per cubic meter). As a rule of thumb: -20 - 30 kg/m3 => Quality for seat and back cushions, low-priced mattresses, -30 - 40 kg/cbm => Standard to upscale quality for seat and back cushions, mattresses, boat, camping or garden cushions etc. -40 - 50 kg/cbm => high to very high and very good permanently elastic quality for a wide range of applications

According to your specifications, we can produce almost all geometries on our wide range of processing options such as punching, water jet cutting, contour cutting, shape cutting or cutting plotter. Which process is best suited for the desired foam cutting depends on the foam used as well as the required quality and quantity.

Polyurethane foams (PU) have an open-cell structure and are mainly used as acoustic foams for sound absorption.

Polyethylene foams (PE) have a closed-cell structure and also have good thermal insulation properties. The very good pressure and impact resistance of PE foam predestines the foam for use in the packaging sector.

Open-cell melamine foams are simultaneously suitable for thermal insulation and sound absorption and have very good fire protection properties.

All Plastazote foams are compliant with the requirements of European Directives 2000/53 / EC (ELV), 2003/11 / EC and 2002/96 / EC (WEEE).

Plastazote foams do not absorb moisture as they all have closed cells.

The durability of PE Plastazote foam is virtually limitless. In most applications, the foams are used for many decades with consistent quality.

In aggressive chemical environments, or in intense and continuous exposure to sunlight, the life of PE Plastazote can be shortened.

The closed cell foams have a different cell structure than open cell foams. In the closed cell foams, each cell is a complete closed sphere containing air in each cell. In contrast to open-cell foams, closed-cell foams do not allow water, moisture and dust to penetrate the cell structure. The closed-cell foam is ideal for sealing, wherever dust and water must be kept away.

In Switzerland, PE or PUR foams cannot be recycled.

They are disposed of with household waste and are "thermally recycled" in the incineration plant.

This material is welcome in the incineration plant because it has a high calorific value and burns very cleanly.

With open cell/open pore foams, each cell is openly connected to the next cell. As a result the cells are not completely closed, water, moisture and dust can get into the cell structure.