Frequently asked questions (FAQ)

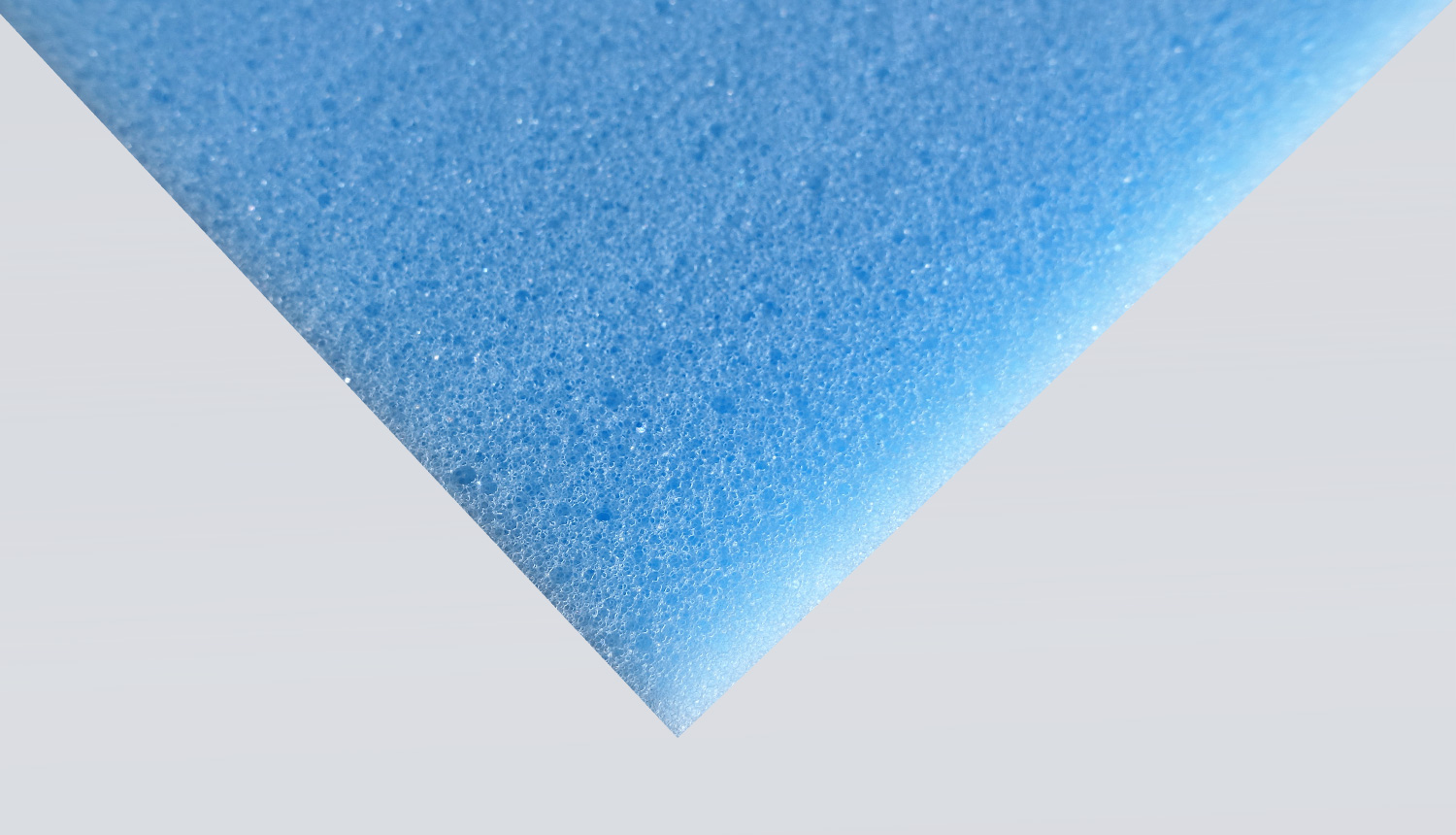

Cushions for armchairs, chairs, sofas, lounge camping mattresses and much more.?? A good cushioning requires filling materials. Foams are particularly suitable for this purpose, which you can obtain from us in various forms or qualities for upholstering armchairs, chairs and sofas. Which foam is the right one for your needs depends on the demands you make on the product. There are foams that are rather soft and are perfectly suitable for soft seat cushions, however, it is rather unsuitable for a lounge chair and another foam might not be suitable for soft seat cushions etc.? The conventional variant and also the cheap one is PUR foam. ?PUR foam can be considered a classic among foams. For various purposes such as seat cushions, seat cubes, lounge cushions, bench cushions etc. this foam can be used. Depending on the density and compression hardness this foam can vary in quality and strength. If you would like to use the upholstery foam in public buildings, restaurants, offices etc., you should pay special attention to fire protection. (e.g. BKZ) Here the following product with BKZ 5.2 would be recommended: Silphon?yellowfoam-FR 40 kg/m3 yellow Fire certificate?? ? The density and compression hardness of the upholstery foam should be in an optimum ratio to each other. A high compression hardness is an indicator that the foam is not very resilient, as a result the foam is softer at a lower value. It can be said that the higher the density, the more material has been used and the higher the quality of the product. As a result, if you want to use foams for bench rests and harder seat cushions or lounge chairs, you should pay attention to a high compression hardness. Accordingly, foams with a lower compression hardness are suitable for soft seat cushions. In principle it can be said - 30 kg/m3 soft quality for seat and back cushions Here we recommend: Article 2019.0111.0009 Blockware PUR-Ether with 32 kg/m3 colour white? PU-ether foam 30 kg/m3 white 30 - 40 kg/m3 for standard/medium to high quality for seat and backrest upholstery, mattresses, boat- camping or garden cushions etc. Here we recommend: Article 2019.0111.0007 Blockware PUR ester with 35 kg/m3 colour blue PU-ester foam 35 kg/m3 blue ? Or with increased fire protection and higher density: Article 2019.0111.0026 Blockware PUR Ether 40 kg/m3 Colour yellow BKZ 5.2 Silphon?yellowfoam-FR 40 kg/m3 yellow Fire certificate?? 40 - 50 kg/m3 for high-quality to very high-quality and extremely permanently elastic quality for all applications Here we recommend: Article 2019.0111.0003 Blockware PUR Ether 53 kg/m3 Colour white PU-ether foam 53 kg/m3 white".