3D PRESSURE IN RAPID PROTOTYPING

For engineers in mechanical engineering, materials handling or construction, the rapid development and production of prototypes is very important. In the field of additive manufacturing, you can benefit from this rapid prototyping. What is possible and what are your advantages of 3D print produced prototypes, you can find out here.

Definition Rapid Prototyping

Rapid prototyping is generally defined as the rapid production of prototypes based on design data. Based on these prototypes, the responsible persons further develop the planned model before finally starting its serial production. (Read more about the advantages of rapid prototyping here)

Definition Rapid Tooling

Rapid tooling also exists. This is the rapid production of tools or tool inserts. The procedures in rapid tooling essentially correspond to those in rapid prototyping, which is why these two terms are often only separated inaccurately.

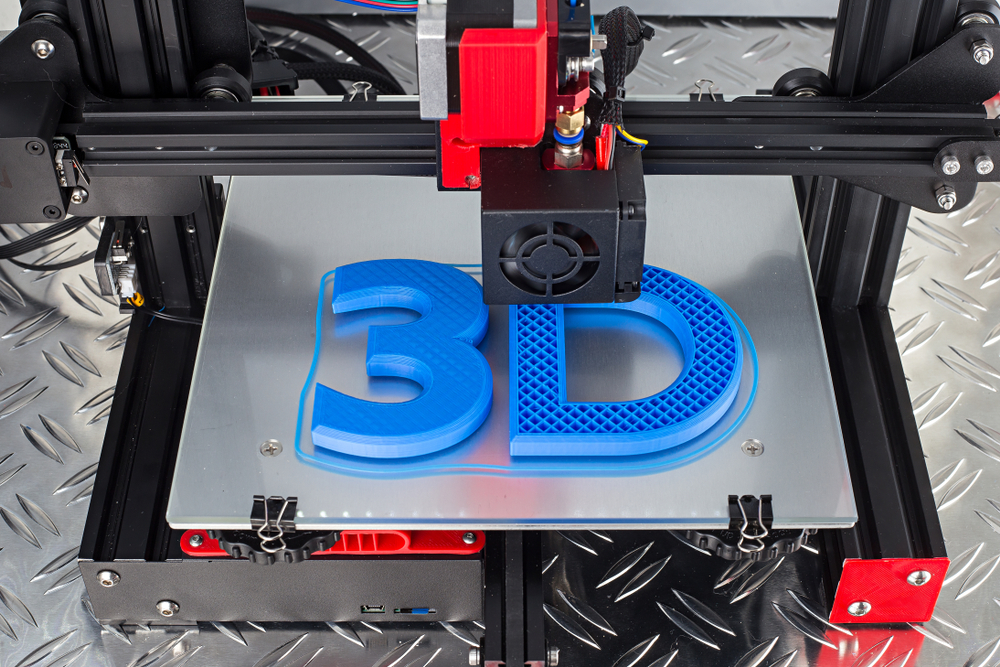

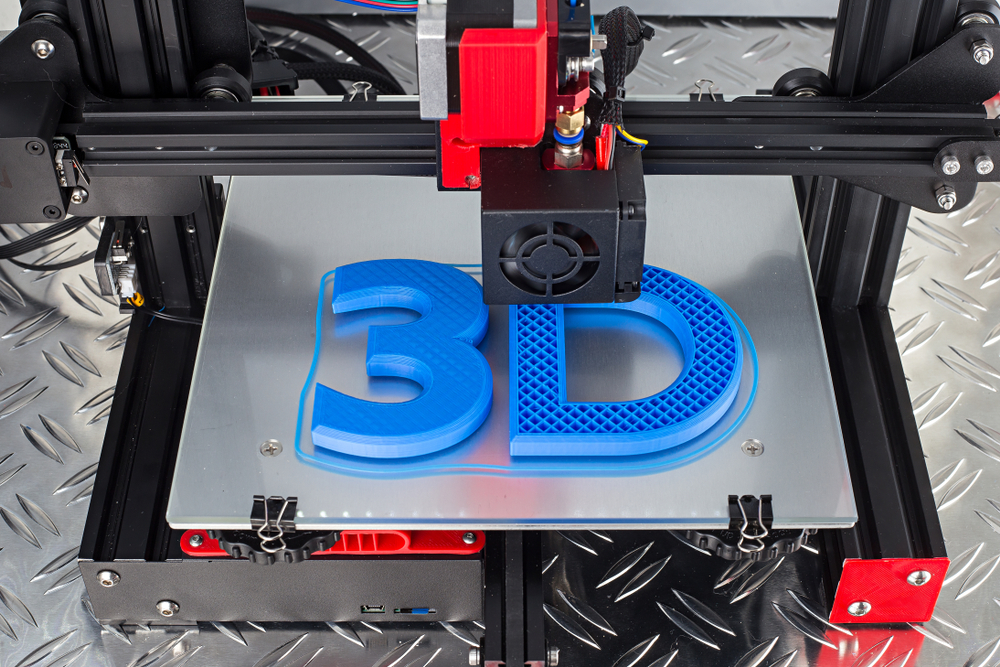

Close interlocking between 3D printing and rapid prototyping

Basically we should remember that not least the industrial demand for rapid prototyping was one of the main driving forces for the development of 3D printing. The developments in 3D printing have therefore been closely intertwined with those in rapid prototyping right from the start, to such an extent that we sometimes find contemporaries who tend to equate 3D printing and rapid prototyping. This equation is of course a misunderstanding, but a very revealing one.

The main advantages of 3D printing for rapid prototyping

The most important advantage of 3D printing technologies for rapid prototyping is of course the time saving compared to conventional methods such as CNC milling or vacuum casting. Since changes are almost always made between the prototype and the final series production, it is even more important not to lose too much time in the production process at every step of the change process, and at the same time additive methods (compared to the usual subtractive ones) result in a significantly lower material consumption. In the end, both factors are so important that we can even risk the thesis that only since the introduction of 3D printing technologies can rapid prototyping be economically implemented on a large scale.

Which additive processes are used in rapid prototyping?

In principle, rapid prototyping works with practically all additive processes. In practice, however, it may not be very practical to produce prototypes in gold or porcelain (using the 3D printing processes available for this purpose). Selective laser sintering (also known as SLS printing) is probably the most frequently used additive process, followed by stereolithography and FDM printing. Polyjet printing, the HP-MJF process, the DLP process, 3D powder printing or, for metal prototypes, selective laser melting are also used.

You too can rely on 3D printing and order your first model online!

In the Vibraplast 3D ecosystem we connect you with the right expert. Be it for printing prototypes in mechanical engineering, architectural models or something completely different. Register now, upload your design and order

Your printed part easily and quickly on our 3D print online platform.