Doors Sound insulation

Doors

Doors Sound insulation

Measures for the sound insulation of a door

Online consulting!?

Doors are often a weak point. These can also be insulated afterwards. In the following you will get ideas how to insulate doors with foam optimally.

A door is present and should be insulated.

Depending on how much space you have or whether the door should continue to be usable or whether you can leave the door permanently, there are two possible solutions. Either you glue directly onto the door, or you clamp our foam into the door shaft or glue it onto a wooden plate which you place in front of the door in a mobile way.

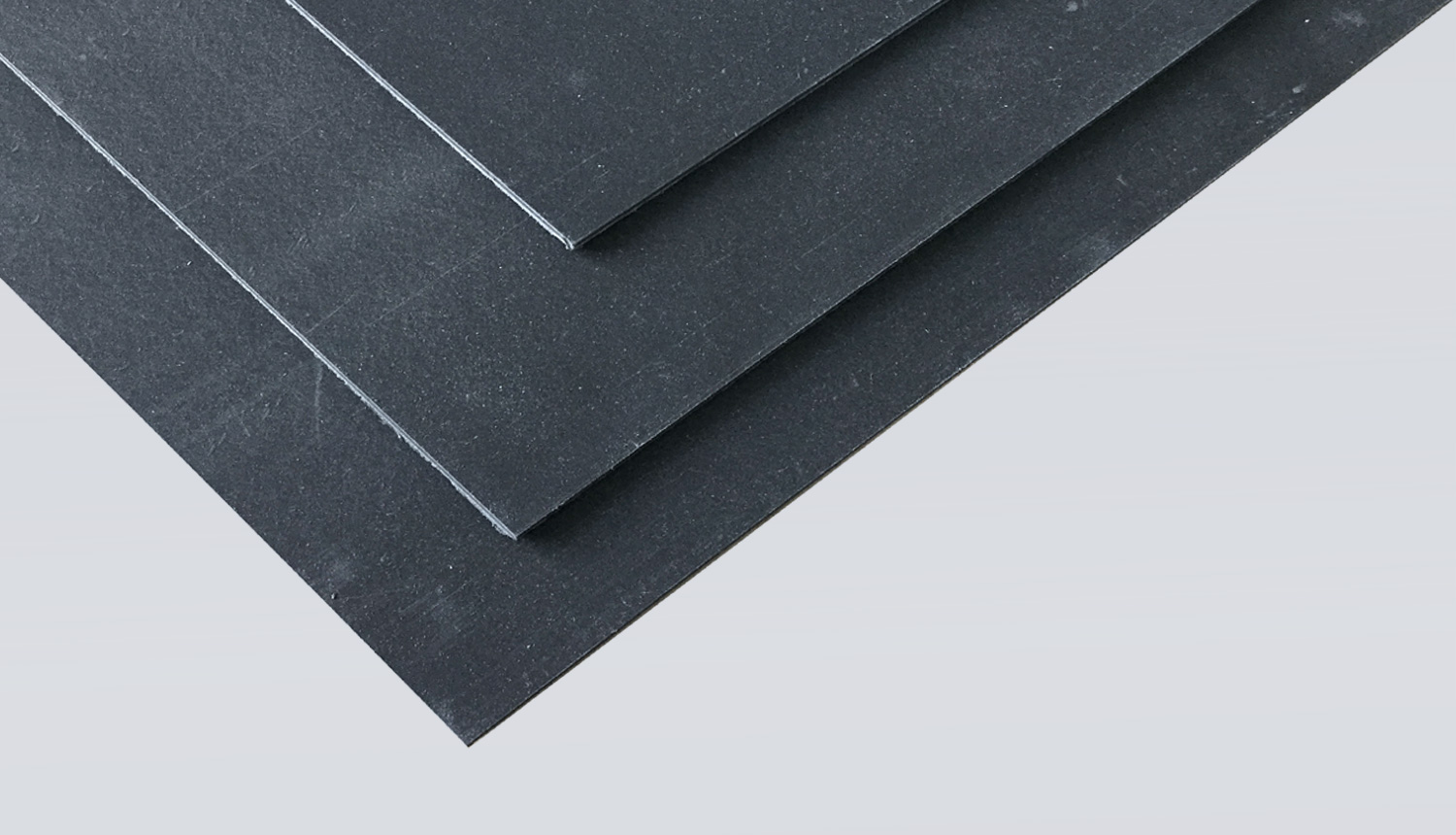

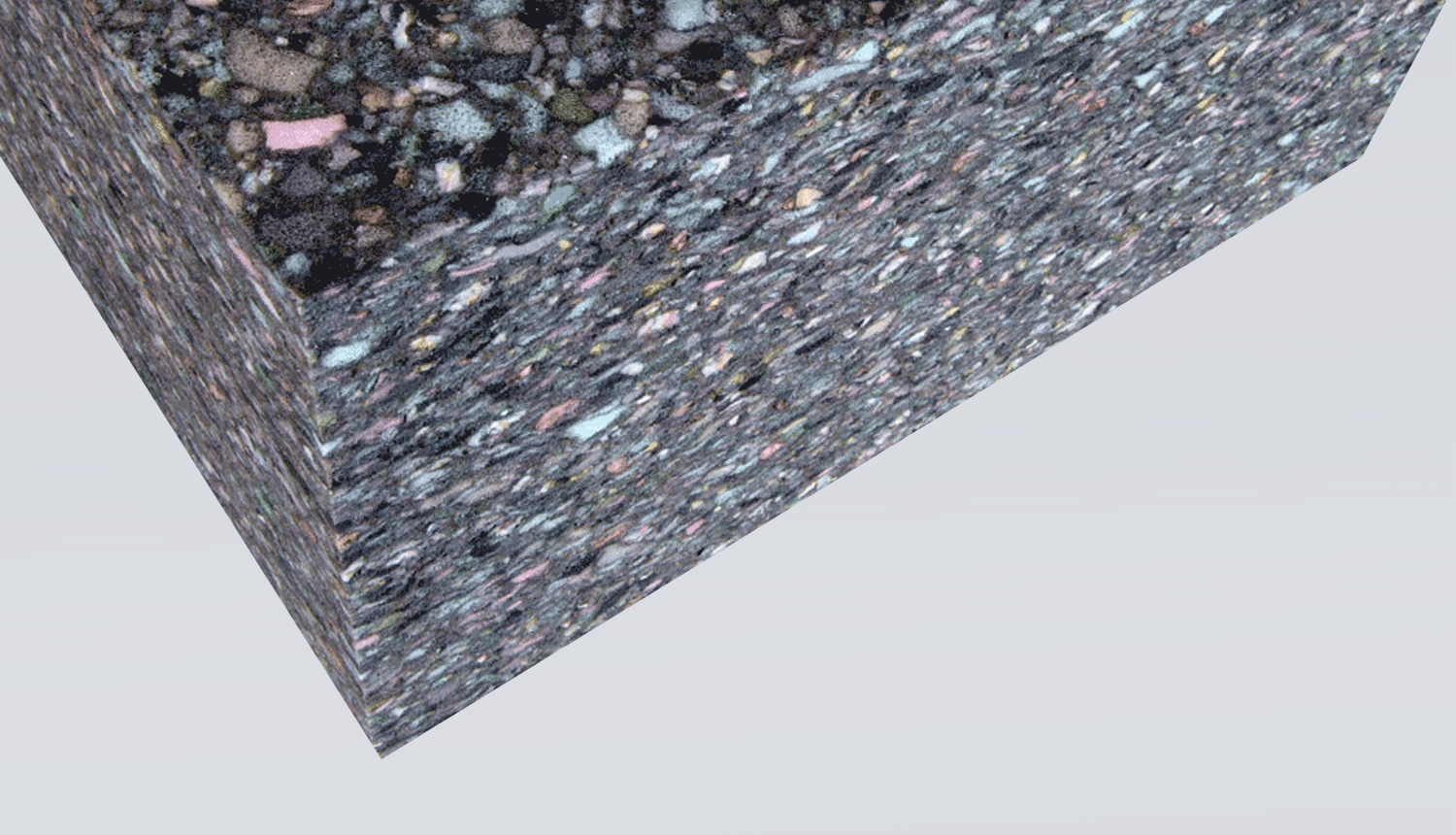

An excellent insulation result can be achieved with composite foam in combination with our Teroform plastic sound insulation foil.

1st possibility: Glue the sound insulation directly onto the door - the door should remain usable

If the door needs to be opened from time to time, you should have the foam cut to the size of the door. Please remember that the door handle must still be accessible then. You should also make sure that the foam is not too large. If it drags on the floor, it will rub off quite quickly and crumble.

If you want to keep the structure as thin as possible, first glue our Teroform plastic sound insulation foil directly onto the door and then our composite foams - ideally on both sides of the door so that the insulation is as strong as possible. The thicker and heavier (100/140/170/200/250 kg/m3) you choose the composite foam, the better the insulation will be. In any case, you should at least apply this insulation on the side where the noise is generated. In order to increase the adhesive strength of the Teroform plastic sound insulation foil, we recommend using an additional mounting adhesive, since the Teroform plastic sound insulation foil and the composite foam are very heavy. The surfaces should be completely coated with a notched trowel.

If you have a lot of space, our 3-layer construction is more efficient - here you first glue our composite foam, then the plastic sound insulation foil and then again a composite foam. The thicker, the heavier (100/140/170/200/250 kg/m3) you choose the composite foam, the better the insulation. The structure will normally be thicker - be careful how far you want to open the door, otherwise the foam will hit the door frame when you open it.?

The first composite foam panel is best bonded with one of our strong assembly adhesives.

Disadvantage: The door is glued directly and of course there will be some remains on the door, which can only be sanded off when dismantling.

2nd possibility: You clamp sound insulation in the door shaft - without gluing

If you do not want to glue the door, you can also simply order a large composite foam panel from us, the thicker, the heavier (100/140/170/200/250 kg/m3) the better, and clamp it in the door shaft and remove it again if necessary. The length and width of the panel should exceed the door shaft by 10 mm - 20 mm each, so that it can be clamped well and holds well.?

3. possibility: glue the sound insulation directly onto the door - door must not be usable anymore

If you don't have to open the door anymore, then choose the 1st option and simply glue, as already written, a composite foam as thick as possible directly onto the door or use the 3-layer construct described above (composite foam - plastic insulation foil - composite foam) and glue it directly onto the door. You can do this on both sides of the door to achieve maximum insulation.?

Product recommendation

For the composite foam we recommend a thickness of 50 mm with a density of 140 kg/m3 Art. No. 2313.0140.0050 for the plastic sound insulation foil Teroform with a thickness of 1.25 mm Art. No. 2302.0948.0131 and for the assembly adhesive the Ergo 6305 with Art. No. 3502.0111.0021.

We will also be pleased to cut the panels to your desired dimensions.?