Gym + fitness equipment

Online consulting!

Various fitness training devices such as treadmills, ergometers, vibration plates, weight benches, steppers etc. are also increasingly used in private households, which again and again leads to disturbing noise and thus to complaints from the neighbours. By using these devices, the material vibrations are generated which are transmitted to walls and ceilings as structure-borne sound. To prevent this from happening, fitness equipment must be decoupled from the floor.

The universally applicable acoustic composite low expansion foam with a density of 140 m3 is ideal for vibration insulation and against vibrations and structure-borne noise from the fitness equipment.

The compound heavy foam with a density of 140 kg/m3 with a thickness of 30 - 50 mm (depending on size and weight) is placed under the fitness equipment to isolate the vibrations.

In addition, a stable wooden plate should be placed on top of the composite heavy foam to distribute the weight of the fitness equipment evenly. For the training with weights, where the more disturbing noise emissions are mainly caused by putting the weights down or putting them on, the composite heavy foam is also very suitable, but an additional wooden plate is not necessary.

Another excellent material to eliminate vibrations from fitness equipment is the Vibra?syl insulation mats which can be adjusted exactly to the respective fitness equipment (size/weight/application) and excellent results can be achieved somite.

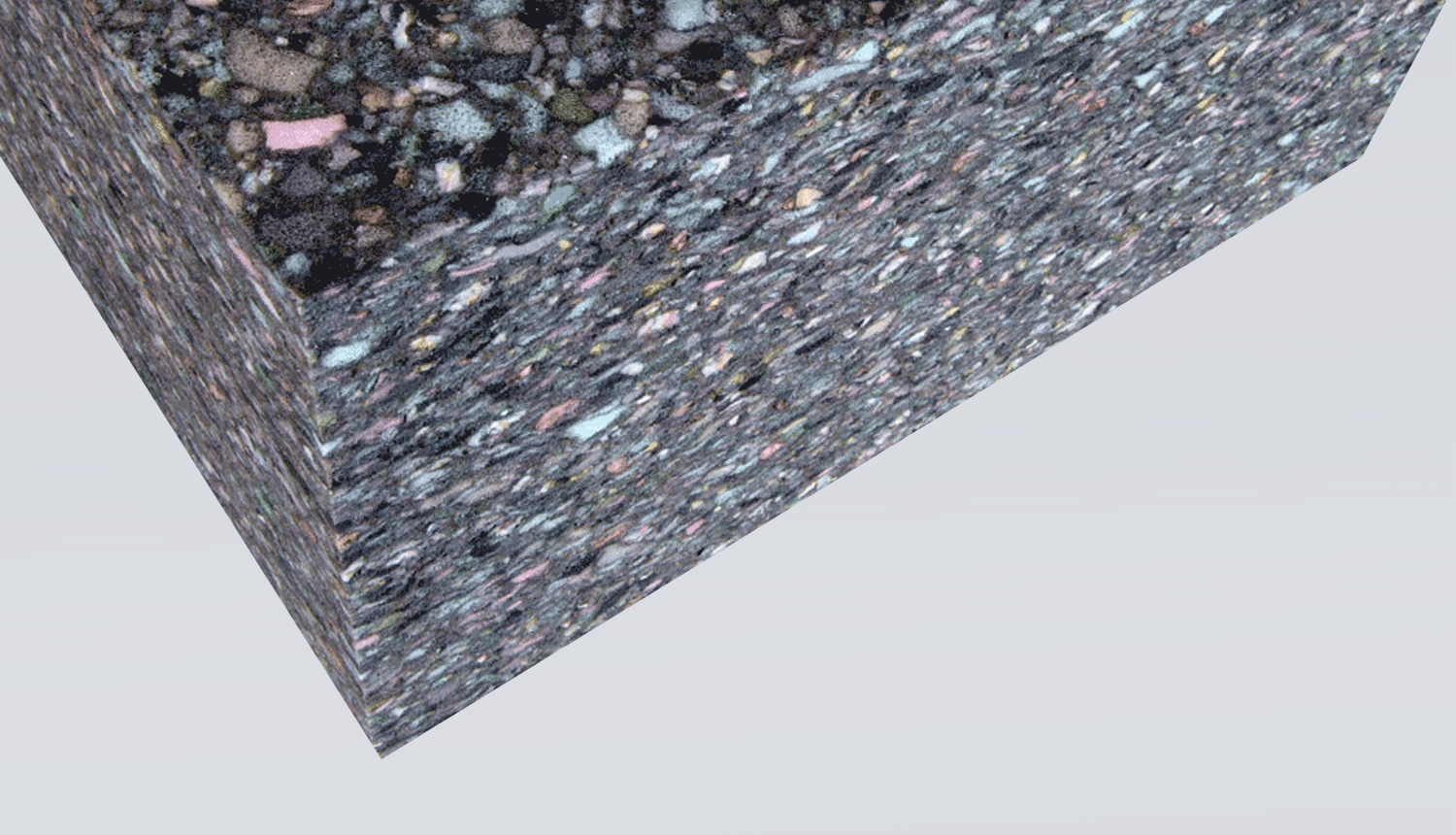

Our range of rubber granulate slabs are also suitable as sound-insulating flooring for fitness rooms. They are tough and permanently elastic and have a high compressive strength and a density of 980m3.

For normal use, a rubber granulate covering of approx. 4-10 mm can be used, depending on the load. For heavier weights, the floor covering can be combined with an acoustic composite low expansion foam with a density of 140 m3 (laid under the floor or as an additive above the floor covering) to achieve optimum shock absorption. We can cut the mats to a maximum length of 3900 mm and a width of 1250 mm.

Attention:

The rubber should not be laid on a parquet or tile floor, as the impact of the weights could still affect it.

Frequently asked questions (FAQ)

Generally speaking, structure-borne sound is sound that propagates in solid bodies such as steel, concrete, etc. through vibration.

Structure-borne sound is sound that propagates in a solid body. When sound is transmitted to a solid body, the latter is set into vibration by the sound transmission. Thereby the sound propagates e.g. over thin-walled metal sheets or over the masonry.

The well-known effects of structure-borne noise result in the unavoidable need to create effective vibration insulation. A technologically relatively simple type of structure-borne sound insulation is achieved by installing an intermediate layer as close as possible to the source of interference, which interrupts the path of the sound vibrations. Motors, for example, are placed on specially designed vibration insulation bodies, thereby making them a vibration system that is almost independent of the environment or support. The same applies to building floors which are periodically subjected to powerful horizontal and vertical impulses at the same time, which are then freed from vibrations both horizontally and vertically by insulation.

Vibrations and structure-borne noise are vibrations and can be positively influenced by applying the following basic principles of vibration reduction or by design measures.

Vibration insulation, structure-borne sound insulation and impact insulation design measures

Structure-borne sound insulation, also called vibration insulation, is a vibration insulation for frequencies above 40-50 Hz. It reduces the transmission of structure-borne sound which is emitted by machines or equipment and spreads in solid bodies (steel girders, concrete floors etc.) and is disturbingly radiated as airborne sound.

Vibration damping is the conversion of mechanical kinetic energy of a vibrating system into another form of energy, e.g. heat.

Bearing dimensioning (with Vibrasyl)

Engine weight?

Machine type?

are large moving masses present? (stability)

Passive or active insulation

Number of bearing points?

Position of the bearing points to the machine (stability)

even load on the bearing points? (center of gravity)

Dimensions of the individual bearing points? (area)

the supports must be smooth at the bottom

If there are more than 3 bearing points, all elements must spring in evenly (assembly)

this information is entered into the Vibraplast calculation program and the corresponding Vibrasyl is determined.

Check/specify natural frequency because of possible resonances.