Skater park

Leisure and sports

Skater park

Online consulting!

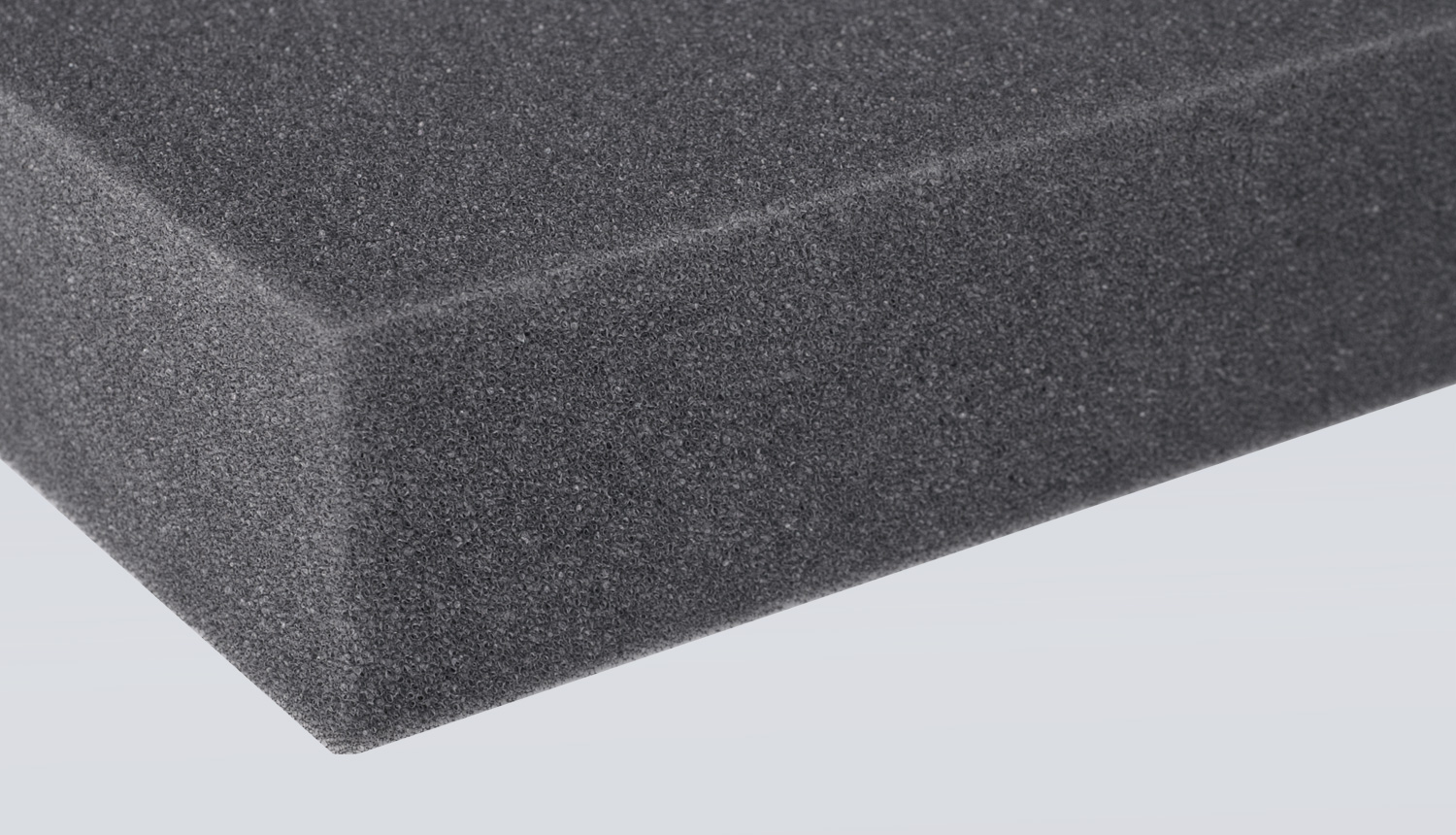

In Switzerland more and more skateparks are being built to create better possibilities of leisure activities for children, teenagers and adults. Obstacles and qarterpipe, halfpipe handrail ecc are built especially for the needs of athletes and acrobats. Through the use of these obstacles there are always disturbing noise emissions which are caused by the lack of soundproofing of the equipment sheets.

Here we can help with the following possibilities and products:

soundproofing of sheet metal with acoustic heavy foil

Noise generation in vehicle construction or mechanical engineering is caused by the inherent vibration of the various sheets.

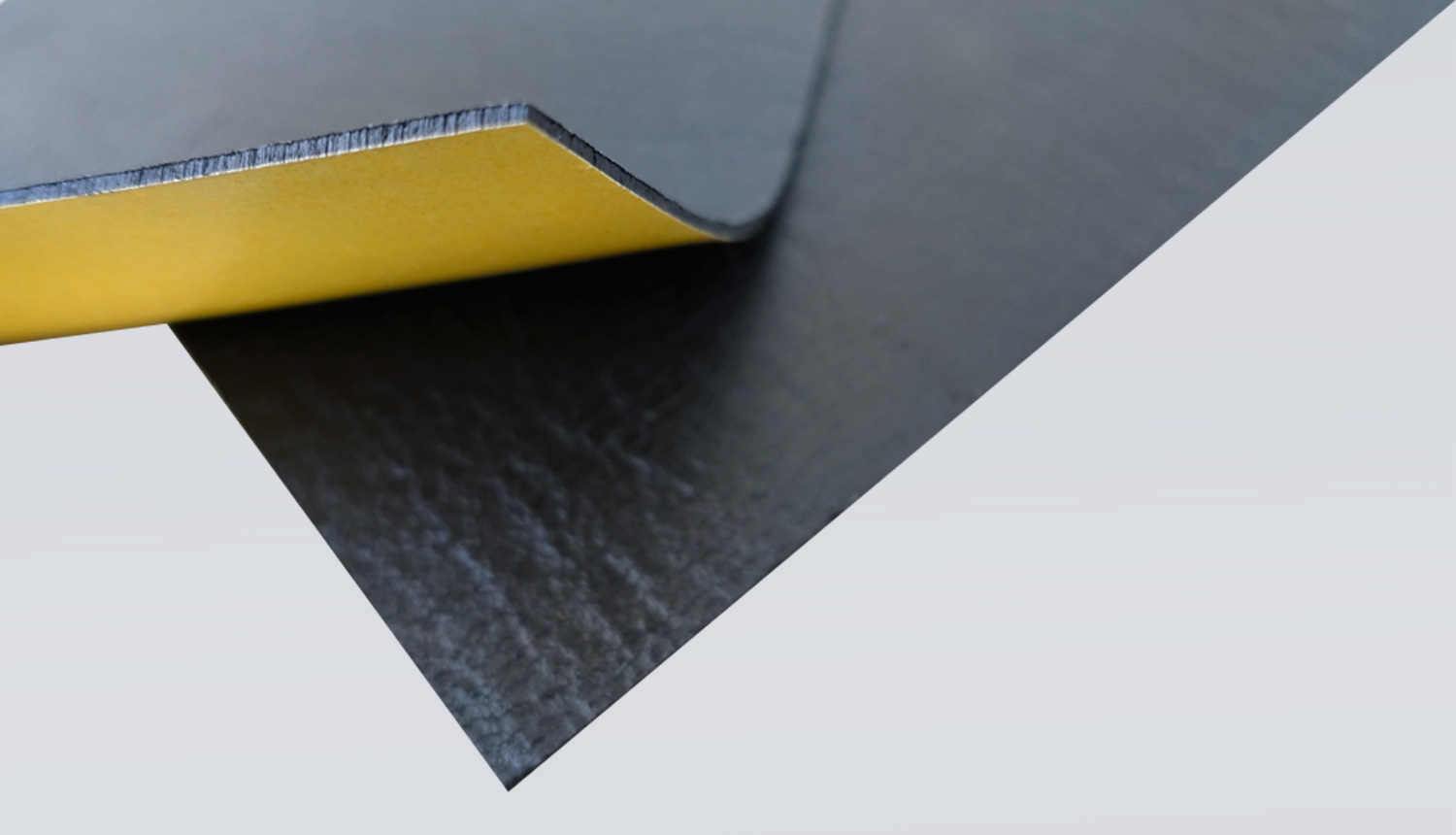

In order to achieve a so-called anti-drumming of sheet metal, the mass of the sheet metal and metal parts should be increased. The use of acoustic heavy foil (anti-drumming mats) has proved particularly effective in this context, for example in vehicle construction but also in the area of machine cladding. Thanks to a self-adhesive layer, the flexible acoustic heavy foil can be bonded to the respective metal sheets, thus providing sound insulation. The thinner the sheets are and the heavier the heavy foil, the better the sound insulation. We can recommend the following products:

Teroform? plastic heavy foil

or

Terodem? bitumen heavy foil

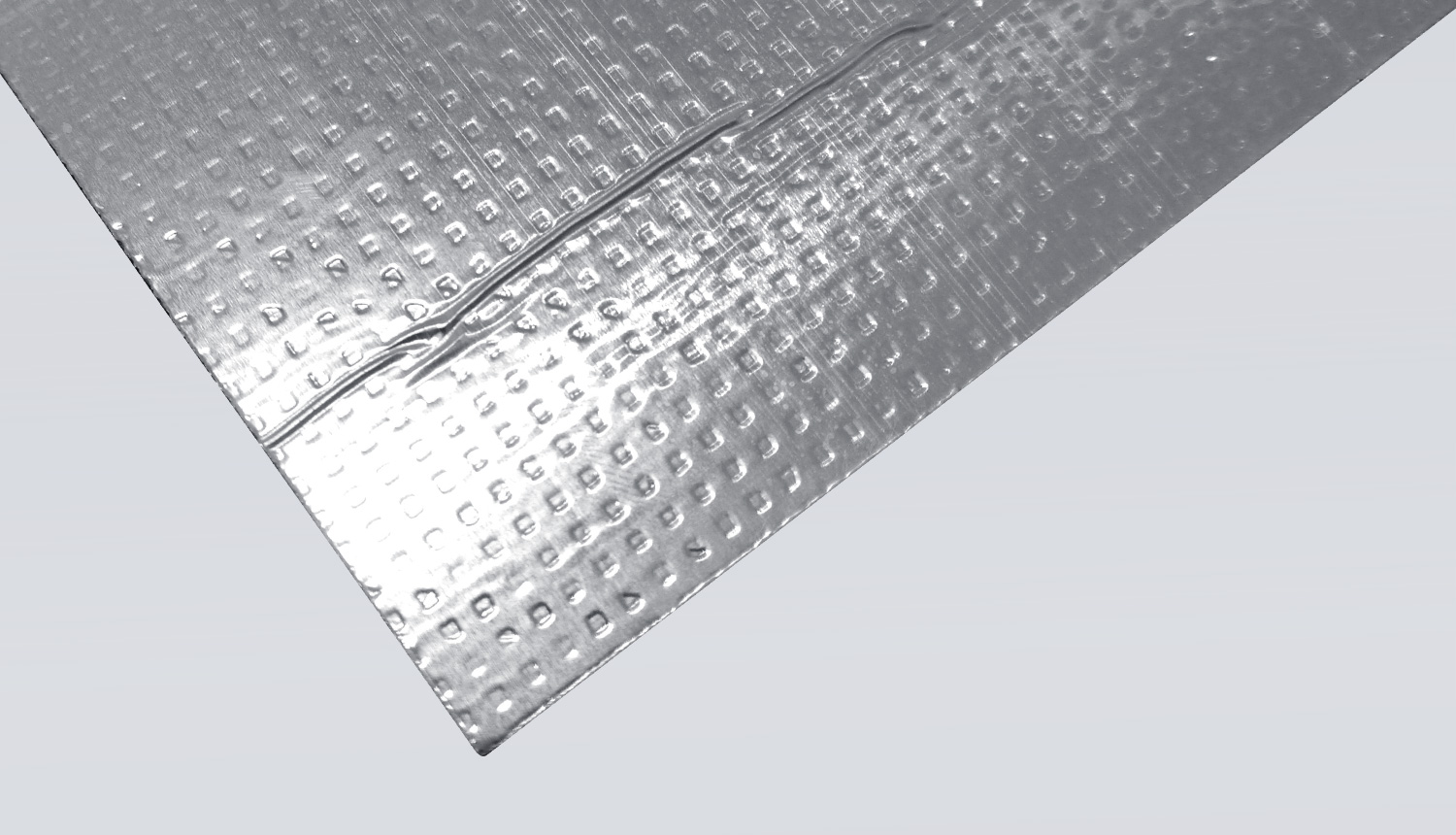

Thermoplastic mixed plastic heavy foil with aluminium surface for sound insulation

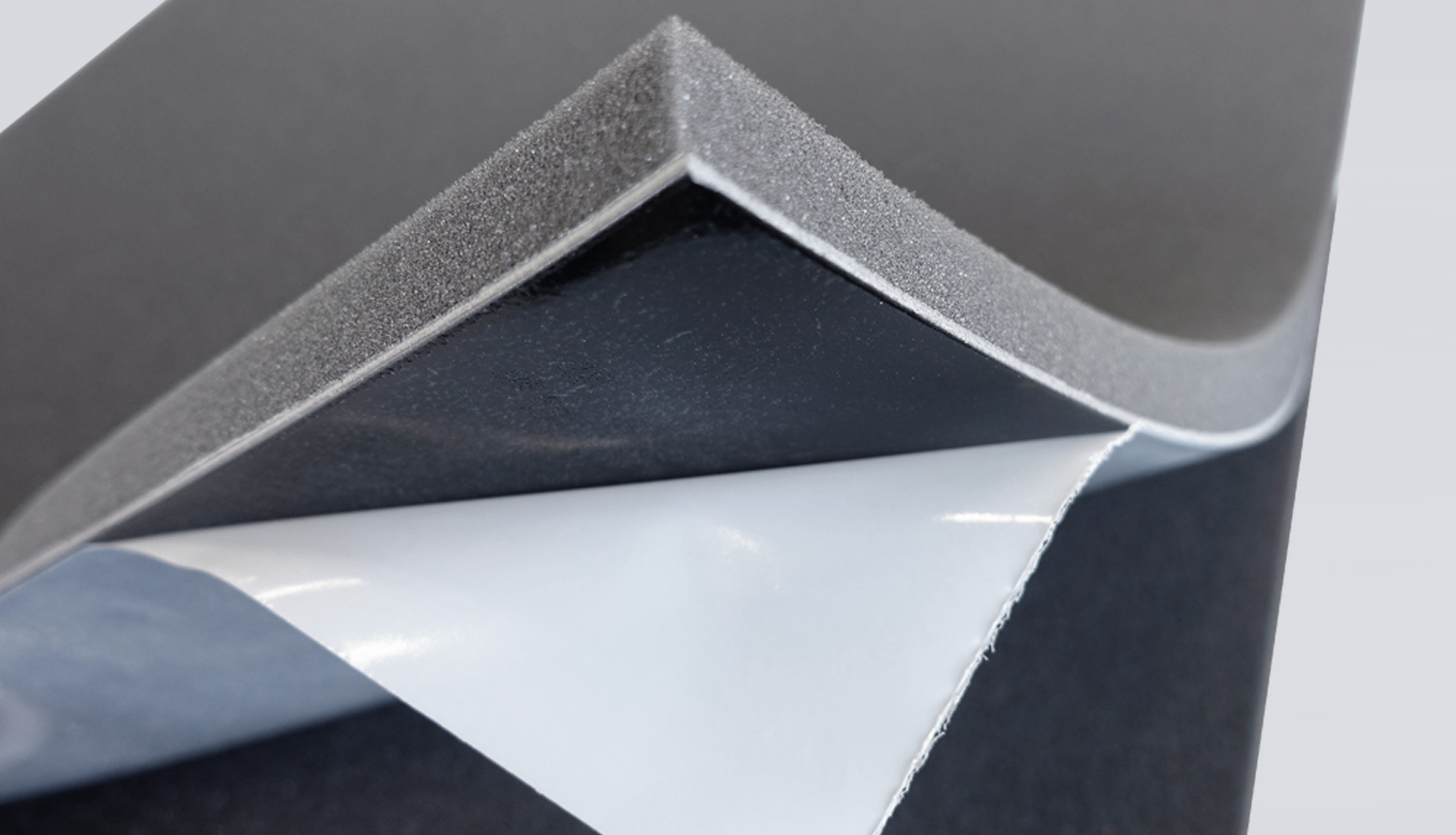

The VibraRail sound insulation foil is a thermoplastic mixed plastic heavy foil with aluminium surface, which is mainly used for the insulation and damping of metal sheets. The VibraRail sound insulation foil is particularly suitable where a product is required for both airborne sound insulation and structure-borne sound insulation. If required, a sound absorbing mat can be glued to the aluminium surface to reduce airborne sound. We can recommend the following product:

Sound insulation foil Vibra?Rail

Frequently asked questions (FAQ)

Generally speaking, structure-borne sound is sound that propagates in solid bodies such as steel, concrete, etc. through vibration.

Structure-borne sound is sound that propagates in a solid body. When sound is transmitted to a solid body, the latter is set into vibration by the sound transmission. Thereby the sound propagates e.g. over thin-walled metal sheets or over the masonry.

The well-known effects of structure-borne noise result in the unavoidable need to create effective vibration insulation. A technologically relatively simple type of structure-borne sound insulation is achieved by installing an intermediate layer as close as possible to the source of interference, which interrupts the path of the sound vibrations. Motors, for example, are placed on specially designed vibration insulation bodies, thereby making them a vibration system that is almost independent of the environment or support. The same applies to building floors which are periodically subjected to powerful horizontal and vertical impulses at the same time, which are then freed from vibrations both horizontally and vertically by insulation.

Structure-borne sound insulation, also called vibration insulation, is a vibration insulation for frequencies above 40-50 Hz. It reduces the transmission of structure-borne sound which is emitted by machines or equipment and spreads in solid bodies (steel girders, concrete floors etc.) and is disturbingly radiated as airborne sound.

Tedrodem? Kobination sound insulation mat has the BKZ 5.2 (hardly combustible with medium smoke formation)

The basic rule when using bituminous or plastic heavy foils as anti-drumming when bonding sheeting is: The sheet thickness x 2 gives the thickness of the anti-drumming foil, 2/3 of which is applied to the surface.

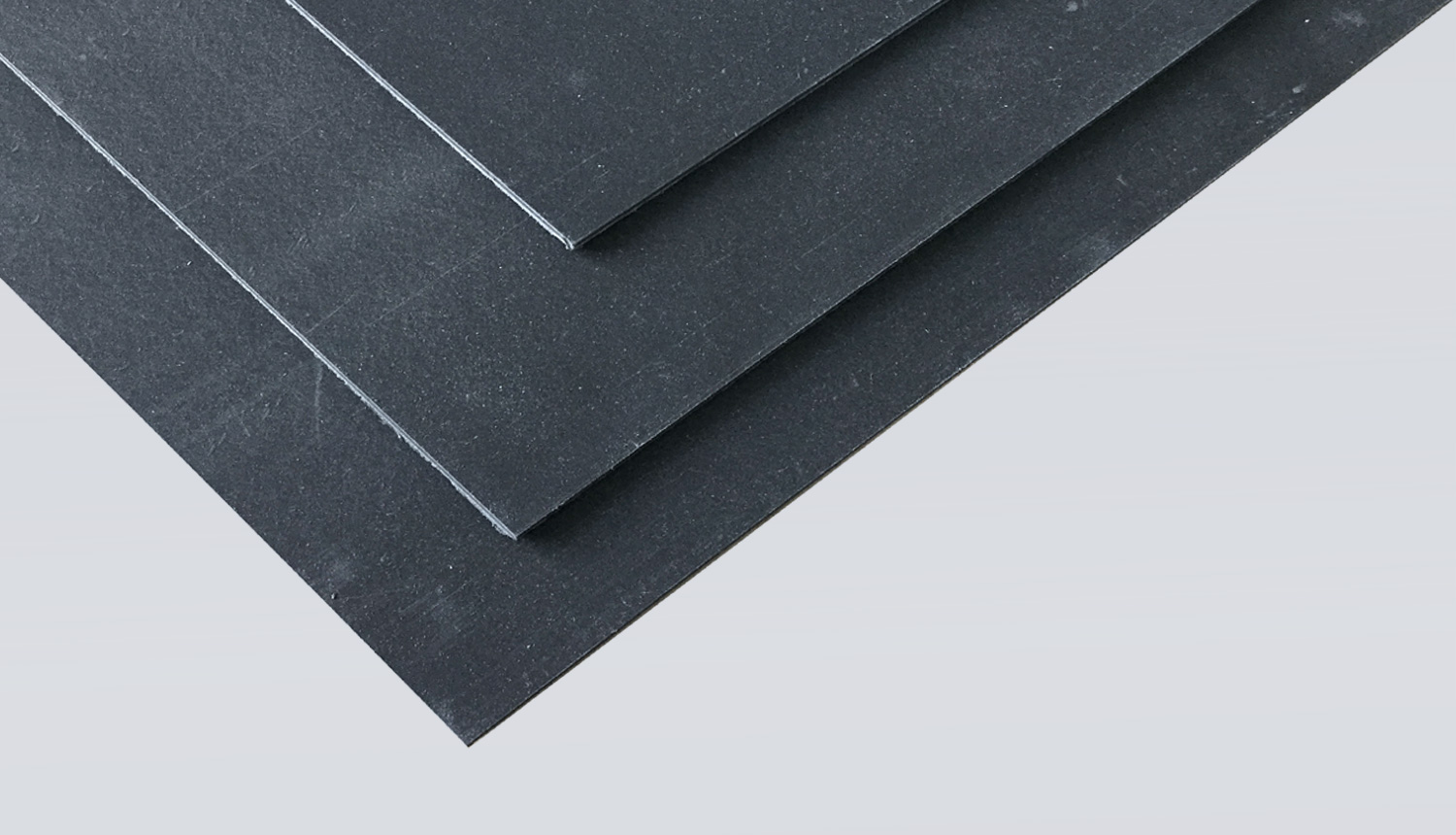

Through the principle of mass increase (weighting), heavy foils for sound insulation bring about a decisive improvement in the (airborne) sound insulation properties of lightweight construction elements made of wood, wood-based materials, plasterboard or thin sheets of steel, aluminium or plastic. Weighting means full-surface connection (gluing) with the light elements. This increases their weight. Thickness and bending stiffness, however, are only minimally increased. Thereby high sound insulation values can be achieved with slim constructions.

In addition, due to their high internal damping capacity, heavy foils have an excellent effect as anti-drumming material, e.g. for thin-walled sheet metal constructions (anti-drumming effect).

Heavy foils are heavy, viscoelastic foils based on plastic or bitumen, which are mainly used to improve the airborne sound insulation (anti-drumming) of thin-walled sheet metal constructions or lightweight construction walls as well as for structure-borne sound insulation (absorption).

The heavy foils from the Vibraplast range have various fire protection certificates such as the fire classification number (BKZ) 5.2 or 5.3 according to VKF / UL 94 / EN 45525 / DIN 4102-1 B2

For vertical (wall) and overhead (ceiling) applications of heavy foils, which place very high demands on the tensile or shear strength of the bond, we generally recommend increasing the strength of the bond by applying an adhesive film to the surface of the construction material to be weighted down (contact adhesive, adhesive spray). Mechanical safety fastenings (metal strips, wooden slats, wide-head nails) can also be provided for this purpose.