Locking cellar + shooting ranges

Leisure and sports

Locking cellar + shooting ranges

Online consulting!

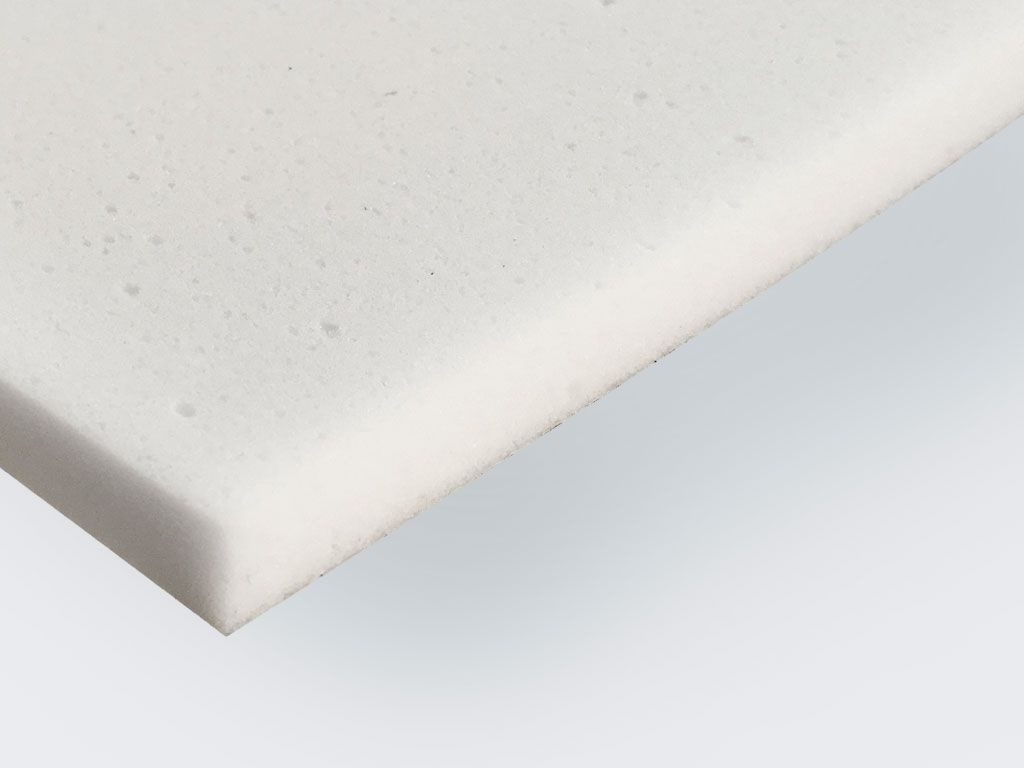

The level for a small caliber rifle reaches 105 dB, for a small caliber pistol 122 dB and for large calibers and shotguns over 130 dB. It goes without saying that shooting generates considerable noise emissions, be it for free-standing open or shot installations. Vibraplast has a wide range of soundproofing products to efficiently absorb the noise in the shooting ranges. The sound absorbers for shooting cellars or shooting ranges comply with the fire protection standard DIN4102 B1, which is mainly met by Basotect melamine foams such as melamine foam Basotect G+ or Bastotect B. All products can be obtained with or without self-adhesive. In order to achieve a high reduction of the sound energy, it is important to ensure that all walls and ceilings are covered over a large area. Furthermore, the open-pored sound-absorbing foam surfaces should be cleaned regularly with a vacuum cleaner.

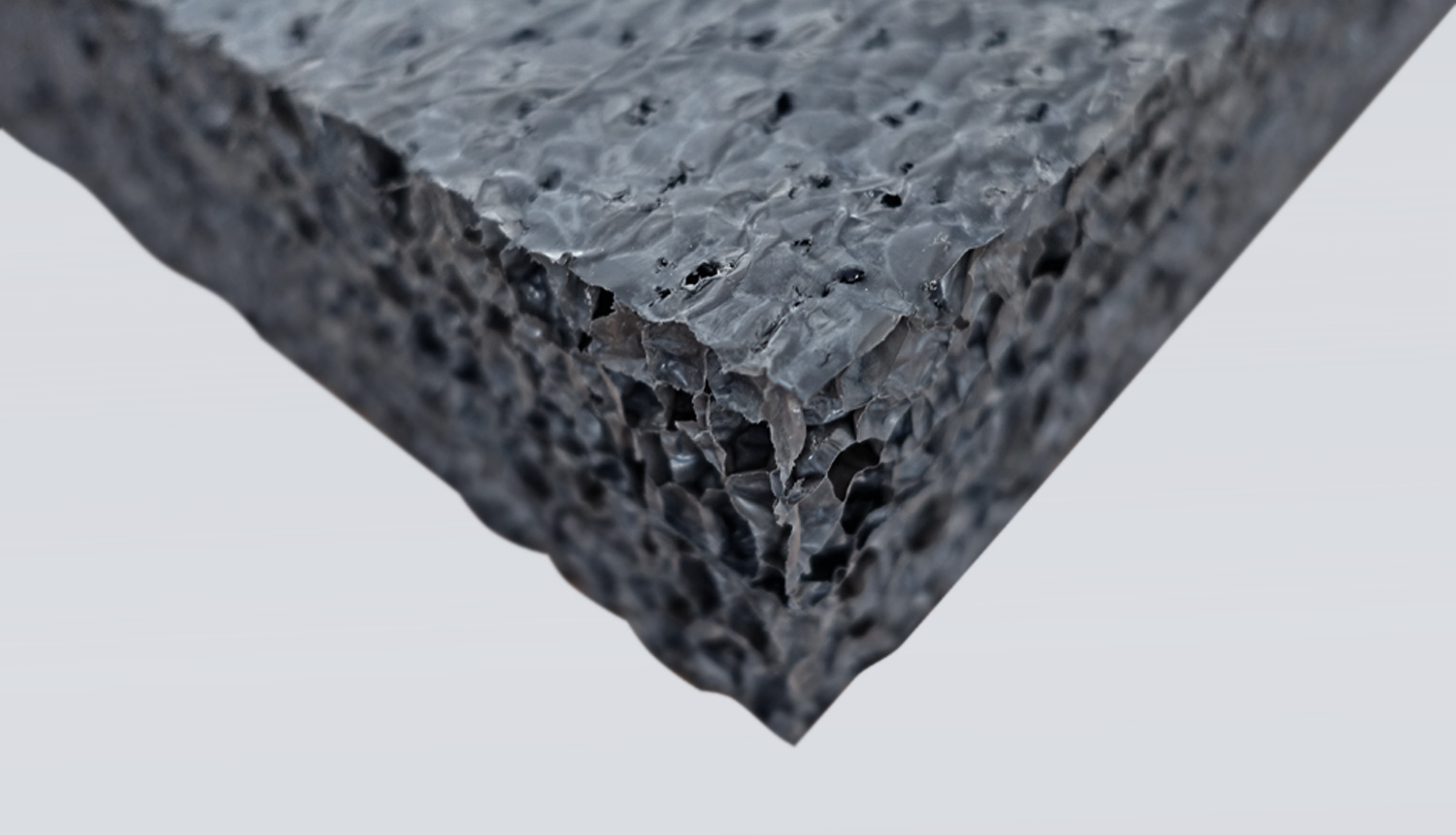

If you need soundproofing for the outdoor shooting range, the closed-cell polyethylene foam Vibra?Quash is particularly suitable for contact with moisture or wetness.

Frequently asked questions (FAQ)

Basotec? melamine foam has the BKZ 5.2 (hardly inflammable with medium smoke formation)

Our melamine foams Basotect? meet both of these requirements in equal measure, highly sound-absorbing and with very good thermal insulation properties.

Small air inclusions or blowholes on the foam top of Bastotec laminate foams can occur and are created during production. Unfortunately these cannot be prevented. However, the air inclusions have no influence on the absorption capacity.

The melamine foam standard panels are supplied as untrimmed raw panels.

The ordered usable dimensions are guaranteed, but protruding material (foam, fleece, SK-foil etc.) is possible.

By using foam absorbers or foam bass traps, the reverberation time is reduced evenly across the entire frequency spectrum. Thereby a clearer and drier room sound is created. With the targeted use of absorbers, especially the disturbing initial reflections from the walls can be attenuated. The booming bass range can be specifically absorbed by bass straps. The sound image of the room through the use of absorbers becomes more homogeneous, softer and more lively.

Materials such as concrete, glass or tiles are placed under sound-reflecting surfaces, which reflect the sound waves up to 100% and as a result do not insulate or absorb the sound. To reduce the volume (sound pressure) and the reverberation time in hard rooms, hard surfaces must be reduced and replaced by surfaces with sound absorbers that absorb the sound.

The sound absorbers allow the sound waves to penetrate the structure and as a result the sound energy is converted into heat or kinetic energy.

In general, the thicker the foam, the better and more efficient the sound absorption.

If mainly middle or higher frequencies have to be optimized, good results can be achieved already from a thickness of about 30 mm.

If low frequencies (bass tones) are involved, thicknesses from approx. 50 mm are advantageous. In general, it should be noted that the lower the frequencies and the higher the room, the thicker the foam panels should be.

If a material is too thin, it only absorbs treble. If the material is thicker, it also absorbs low frequencies

Basically, neither pyramid foams nor nubbed foams are suitable for sound insulation to the outside. These two sound insulation materials mainly reduce noise or reverberation in rooms and are used to absorb sound. Above all, the room acoustics are improved. The nubbly foam as well as our pyramid foam are produced "swiss made" in the Vibraplast AG. The pyramids are produced by cross-cutting on a horizontal contour cutting machine, the nubs are produced with a profiling roller. Since the production of pyramid foam takes longer, the price is correspondingly higher than that of nubbed foam. The panel thickness defines which frequencies are absorbed. The thickness of the foam defines which frequencies are absorbed. Thin foam boards tend to absorb in the higher frequency range, while thicker foam boards tend to absorb in the lower frequency range. For the same material thickness, nubbed and pyramid foams are equivalent. It is up to you to decide which look suits which room better.